Burn-In Test

The Burn-In Test is a semiconductor reliability testing method where test devices are loaded onto a Burn-In Board (BIB), a product designed to match the specific characteristics of each device. These boards are placed in a chamber where a constant temperature of over 125°C is maintained, and voltage and signals are applied to screen for early device failures and evaluate device reliability (life-time).

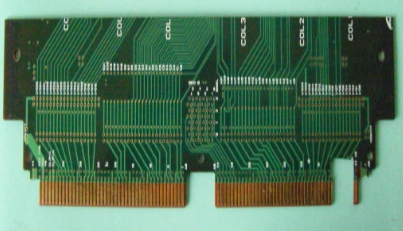

PCB Design

BIBs are configured with multiple sockets and electrical circuits to accommodate various electronic components.

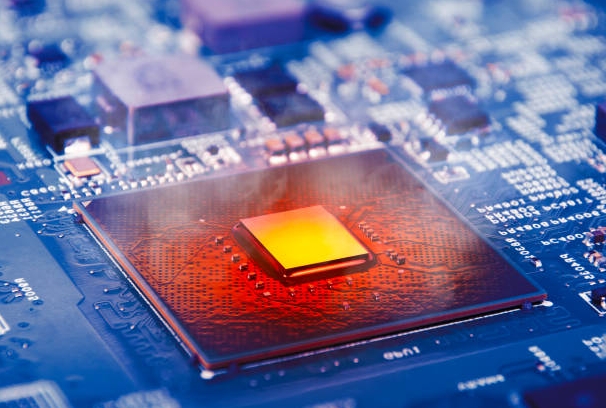

Stress Testing

By repeatedly exposing devices to high currents, voltages, or thermal stress over extended periods, the test verifies whether the components function normally or develop defects after a certain period.

Test Environment

Devices are tested in a Burn-In Oven under controlled conditions to monitor performance degradation or defect occurrence.

Early Failure Detection

Identifies initial failures, preventing defective devices from reaching end-users.

Quality Control

Verifies manufacturing process quality and ensures

that produced components meet consistent quality standards.

Ensuring Product Reliability

Components that undergo the Burn-In process demonstrate increased reliability during long-term use.

This is especially critical in industries requiring high reliability, such as aerospace, automotive, and medical equipment.

Burn-In Board Service

Edge Damage & Other Issues

Burn-In Boards play a critical role in ensuring the stability and reliability of electronic components. However, prolonged use may lead to board damage or component wear. Our Burn-In Board Repair service addresses these issues, extending the board's lifespan while maintaining testing accuracy and reliability.

*Expert Repairs Highly skilled technicians quickly diagnose and restore

all types of damage and defects.

*Quality Assurance Quality verification tests

ensure the restored boards deliver top-level performance.

Cost Efficiency Save on the expense of purchasing new boards

while maintaining stable performance.

Customized Service Tailored repair and upgrade options to meet the specific needs of customers.

lBURN-IN BOARD I/O EXTENDER BOARD -DESIGN & DEVELOPMENT